BARCODE-LABELS

Labelling for every area of application

We are a leading provider of barcode solutions for a wide range of applications and requirements. With our many years of experience and extensive expertise, we develop and implement customised barcode labels for our customers. Our portfolio includes a wide range of 1D and 2D barcodes that are suitable for a wide variety of applications. Whether in logistics, retail or industry - our barcode labels always offer you the right and reliable solution.

What are barcode labels?

Barcode labels are labels that are printed with machine-readable codes. These codes store data in optical form and can be read by scanners or cameras. There are two main types, 1D codes (one-dimensional barcodes) consist of black bars and white spaces in different widths - as we know them from the supermarket, for example. They store simple information such as product numbers or serial numbers. 2D codes (two-dimensional barcodes) consist of small squares or dots arranged in an area (e.g. QR codes or Data Matrix). They can store significantly more information - in some cases up to 1,000 times as much as a 1D code.

The labels themselves are made of special materials that are customised depending on the application. Factors such as temperature, chemicals or the nature of the surface on which the label is stuck play a role. Legal standards or industry-specific requirements also influence the structure.

The term ‘barcode’ is often used generically - but it refers to all types of machine-readable labelling, not just the classic barcodes.

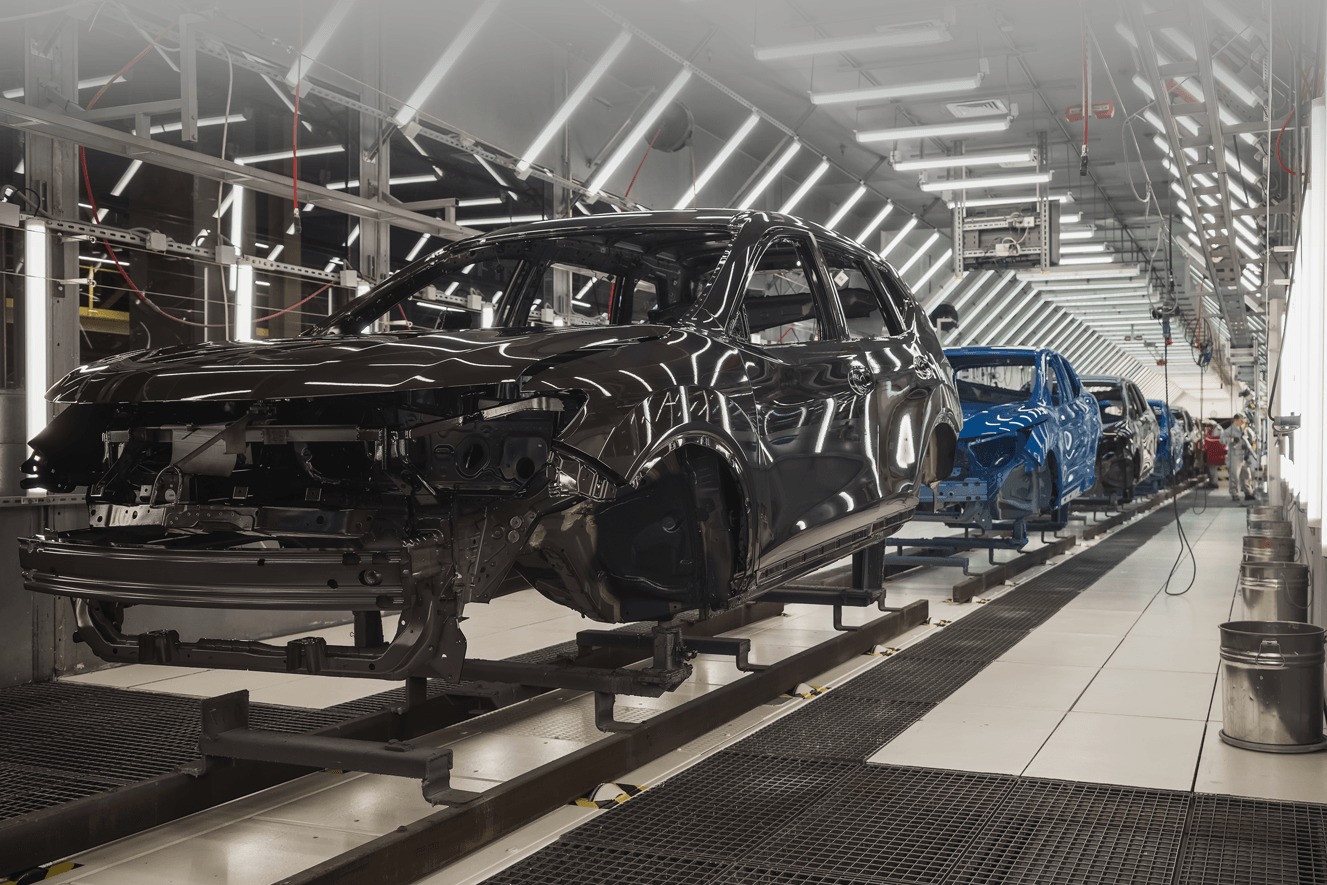

Barcode labels are used in almost all industrial, commercial and service sectors - from ‘A’ for labelling automotive components to ‘Z’ for personal identification in access control systems. The prerequisite is always that a label can be permanently attached, that the printing remains machine-readable for a period of time that is customary for the application and that there is an optical path of vision between the barcode and the reader.

There are standardised barcode typologies, depending on the industry and application, which are defined in ISO/IEC 15418, for example, and specify certain data structures and character sequences. The aim is to enable the cross-industry use of labelling technology and the interoperable, manufacturer-independent use of readers.

What makes good barcode labels?

Solutions from the Plöckl Media Group

Why Barcode labels from PMG?

Development

We use our extensive expertise to design and develop your customised product solution according to your wishes.

Production

We leave nothing to chance when it comes to production. We use state-of-the-art machinery and equipment and guarantee the highest precision for every single label.

Quality

We use state-of-the-art camera control systems for quality control and thus guarantee the highest quality through our 100% final inspection.

Reliability

You can always rely on the comprehensive expertise and consulting skills of our employees. From the initial contact to the final realisation of your project and beyond, we are at your side competently and flexibly at all times.

Quality

and

reliability

Barcode labels from PMG stand for the highest quality and reliability. Strict quality controls and the use of high-quality materials ensure that our labels fulfil your requirements even under demanding conditions. Our labels are robust and resistant to heat, cold and moisture and are ideal for use in industry, retail and logistics. We work with you to develop solutions that are precisely tailored to your requirements.